Self-healing Battery Electrodes/Electronics

We are exploring the translation of self-healing concepts in structural materials to new functionalities including microelectronic circuits and battery electrodes. Our research is focused on improving reliability and lifetime of critical battery and electronic circuit components. A common cause of premature failure in such components is fracture and loss of conductivity. Our approach is predicated on the incorporation of microcapsules containing a conductive fluid that is released locally to the damage zone, restoring conductivity and maintaining component performance.

In battery electrodes we have incorporated microcapsules that contain a conductive filler dispersed and stabilized in a solvent. A wide variety of capsules have been developed and their performance in controlled fracture tests are investigated. The stability and performance in situ within battery cells is currently being pursued.

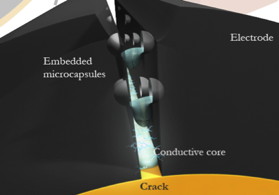

Self-healing battery electrode schematic. Microcapsules containing a conductive filler are embedded within the electrode. The microcapsules rupture and release their contents under the influence of volumetric expansion and contraction during battery cycling as lithium is transported into and out of the electrode.

For microelectronics circuits thermomechanical fatigue leads to failure of conductive pathways in highly integrated circuits and loss of function. We are developing autonomous conductance restoration techniques for circuits that rely on the triggered release and transport of a conductive core material to the site of damage. Using a conductive liquid metal (Ga-In alloy) we have shown greater than 99% restoration of conductance in model circuits.

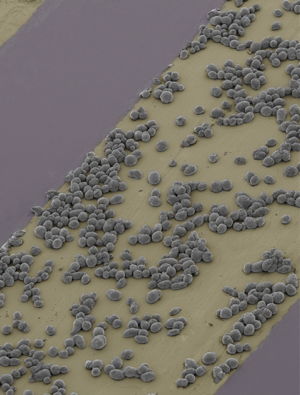

Poly(urea-formaldehyde) microcapsules containing Ga-In liquid metal deposited along a gold circuit line prior to fracture and recovery of conductivity (Cover image, Advanced Materials Volume 24, Issue 3, 2011).