Microvascular based self-healing materials can overcome the limitations of capsule-based healing systems in which a finite supply of healing agent restricts the number of healing events possible. Upon damage initiation, cracks intersect the networks triggering the release of healing agent(s) into the damaged region where they mix and repair the damaged material. Our research group has been able to successfully incorporate an internal vasculature into a wide range of materials including elastomers, thermoplastics, thermosetting polymers, composites, metals and ceramics. Our focus has centered on structural polymers and fiber-reinforced composites due to their increasing demand and growth in modern structural applications.

|

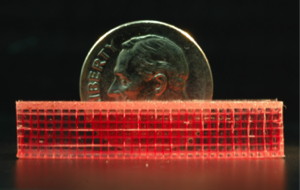

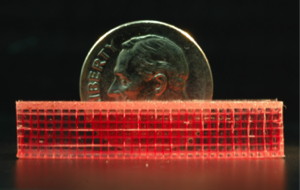

Microvascular epoxy sample. 3-D microvascular network (300 micron channels) is created by robotically controlled deposition (RCD) of a fugitive wax scaffold encapsulated with a structural epoxy resin. The simple grid network is evacuated by mild heating and application of vacuum after epoxy solidification. The hollow network is then infiltrated with a healing agent. Ref: Toohey et al. Nat. Mater. 2007 |

|

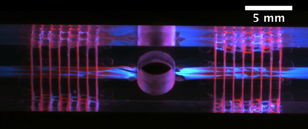

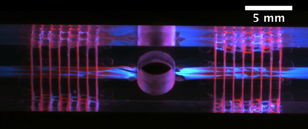

Self-healing epoxy bulk healing sample. Dual (isolated) networks are filled with two-part epoxy healing agents (fluorescently dyed red and blue). A central mid-plane crack is propagated along the mid-plane of a Double Cleavage Drilled Compression (DCDC) specimen during axial compression. The crack ruptures both networks releasing the healing agents into the crack plane where in situ mixing leads to polymerization and healing on a repetitive basis. Ref. A.M. Hamilton, PhD Thesis, 2011. |

|

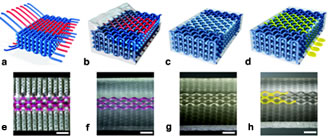

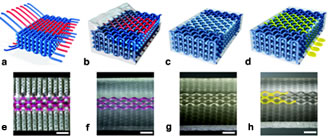

Vaporization of sacrificial components (VaSC) fabrication procedure to create microvascular networks in fiber-reinforced composites. Schematic diagrams of a) straight warp and weft yarns (light blue) with interwoven Z -fiber tows (dark blue) and sacrificial fibers (red) to form an orthogonal 3D structure; b) epoxy resin infuses the preform; c) thermal depolymerization and monomer vaporization results in a 3D microvascular network integrated into a structural composite; d) fluid (yellow) fills the microvascular channels. Optical images of e) sacrificial fibers (pink) woven into 3D glass fiber mat; f) resin infiltrated 3D composite; g) empty microvascular network; and h) fluid filling the channels. Scale bars = 5 mm. Ref: Esser-Kahn et al., Adv. Mater., 2011. |

|

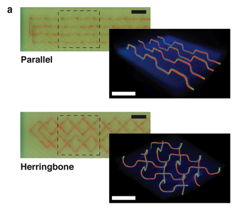

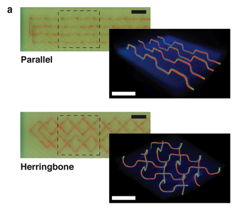

Self-healing glass/epoxy composites. (a) Pre-vascularized, fiber-reinforced composite laminate samples showing sacrificial fiber (red) stitching patterns (scale bars = 10 mm) and post-vascularized, X-ray computed microtomographic reconstructions of vascular networks filled with eutectic gallium-indium alloy for radiocontrast (scale bars = 5 mm). Ref: Patrick et al. Adv. Mater., 2014.

1. Patrick, J.F.; Hart, K.R.; Krull, B.P.; Diesendruck, C.E.; Moore, J.S.; White, S.R. and Sottos, N.R. Continuous self-healing life cycle in vascularized structural composites, accepted to Adv. Mater. |